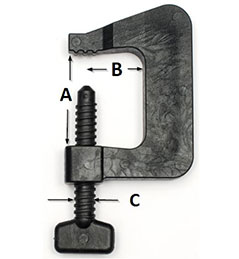

Wedge Clamp

Developed primarily for use in metal surface treatment plants as a special clamping tool.

Capable of withstanding the corrosive attack of chemicals used in the industry. The wedge clamp secures hollow sections from the inside, allowing anodizing or painting over the entire length of the section. It adapts to templates and sections of different sizes, guaranteeing secure attachment and good electrical contact. As the clamp fits inside the section, there are no external clamping marks, eliminating the need for unnecessary trimming.

- Description

End caps may be added as needed to enhance slip resistance. They can be supplied in titanium, zirconium or ceramic.

Clamps are molded in glass-filled Noryl, for use in anodizing with a maximum operating temperature of 105 ° C, or can be molded in glass-filled Radel for use in painting and electro-brightening. , up to a temperature of 220 ° C.

Small +

Quick and secure fixation

No external clamping marks

No unnecessary size

Reduction of current consumption and effluent costs

Versions for anodizing, painting and electro-thinning